The “Internet of Things,” the term coined to describe the ability of physical objects to connect to the internet and each other, has enjoyed a lot of attention in recent years.

When this technology is applied in our homes, it gives us the ability to control things like internet-connected lighting, appliances, locks, and electronics from our smartphones or computers — whether we’re at home or away from it.

As you can imagine, this technology has applications that go way beyond home use. This tech is also starting to make a big impact on industry. Just as phones have become “smartphones” and homes are becoming “smart homes,” factories have the potential to transform into “smart factories.”

In these factories of the future, workers will be able to leverage machines’ ability to communicate wirelessly to do things like conserve energy, reduce risk, and improve productivity in a number of ways.

Are you ready for the world of smart factories? Here’s what you need to know about Industry 4.0.

What is Industry 4.0?

If industry 1.0 refers to the advent of water- and steam-powered tech, 2.0 was the advent of electricity and its industrial applications, and 3.0 was the beginnings of “computerized automation,” we’re now in 4.0, which combines industrial applications with computerized applications for a whole new level of automation.

Other terms used to describe these advances are “Industrial Internet of Things” or simply the “Industrial Internet.”

Experts may disagree about whether the latest advancements in machines’ ability to connect to the internet constitutes a revolution on par with the steam engine. But it’s hard to argue that manufacturing isn’t in the midst of a significant change, even if that change may have come about incrementally.

As this blog post from Global Electronic Services points out, “This fourth revolution marks the first time that digital, cyber technology has integrated into all levels of manufacturing, to the point where high-tech, cognitive machinery automate intellectual in addition to physical, tasks.”

With the digital tools available now, machines can pass data back and forth between each other and employees with the aim of correcting errors and imperfections, improving production consistency, and keeping employees safer.

In one example of industry 4.0 in action, the Hanover Messe web site reports that one of the world’s largest providers of machine tools uses laser cutting machines with intelligent lenses that automatically alert the maintenance team when a lense is dirty. GE lists some other examples here:

- enabling predictive analytics to detect corrosion inside a refinery pipe

- providing real-time production data to uncover additional capacity in a plant

- driving visibility and control over your industrial control systems environment to prevent cyber attacks

Besides these specific applications, boundaries between factory locations will become less important or even irrelevant as machines and systems can communicate via the cloud. The potential for innovation is vast.

The Technologies of Industry 4.0

Although exact definitions of what constitutes Industry 4.0 vary, the Industrial Internet of Things is a product of several advancing technologies, or what this McKinsey and Company piece calls “disruptive trends.”

Not all of these technologies work together directly, but they all play a role in the factories of the future.

Cyber-Physical Systems

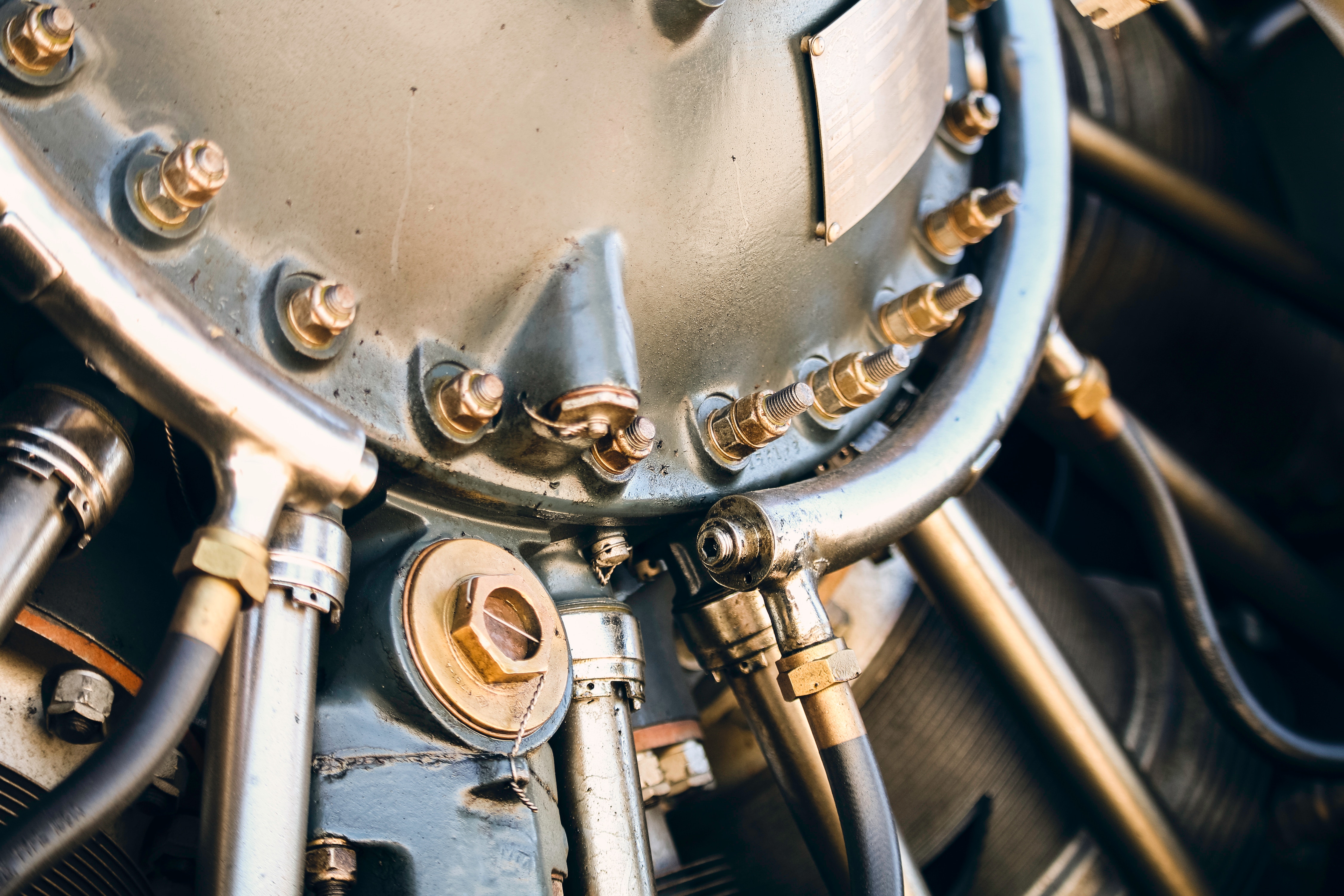

You could say that cyber-physical systems are at the heart of Industry 4.0. “Cyber-physical system” describes any system that combines computer programming with a physical, mechanical tool.

Here’s one published paper’s definition: “A cyber-physical system (CPS) is an orchestration of computers and physical systems. Embedded computers monitor and control physical processes, usually with feedback loops, where physical processes affect computations and vice versa.”

Cyber-physical systems are used in all kinds of industries, including automotive, healthcare, HVAC, and yes, manufacturing.

Industrial Big Data Analytics

The amount and speed of data that computers process — and the speed with which they can process it — continues to grow.

The term “big data analytics” refers to the activity of examining large amounts of data to find helpful patterns, insights, and connections.

As analytics company SAS points out, organizations have been using data for years, with the understanding that “if they capture all the data that streams into their businesses, they can apply analytics and get significant value from it.” The difference is that in the 1950s they used a manual spreadsheet, and today they have way more data and much more sophisticated tools at their disposal.

Even just a few years ago, businesses had the ability to gather relevant info and run an analysis. Today, though, insights can be identified immediately.

Big data analysis is especially important for manufacturing. That’s because the cyber-physical machines that factories rely on each create vast amounts of data constantly, and additional data is created as these machines interact with each other.

Companies are starting to create solutions for manufacturers to gain real-time access to the incredible volume of data that their machines are producing, organizing and displaying it in a way that makes sense. Some of these tools are called Supervisory Control and Data Acquisition (SCADA) applications.

Human-Machine Interfaces

This helpful Machine Design article puts it this way: A Human-Machine interface “includes any device or software that allows you to interact with a machine.”

Examples can be as simple as an on/off switch and as complicated as a touch-screen control panel that you can access on your phone.

As ESA explains, a good HMIs can translate a huge amount of complex data into accessible information, giving operators all the necessary tools to control the production process.

As HMIs improve in the industrial sector, people have better control and clarity over their machines’ operations and their own work.

Newer forms of HMI might even include “augmented-reality systems” like the one mentioned in the McKinsey article in which logistics company workers wear a headset that can help them locate, analyze, store, and track items more efficiently and accurately.

Machine-to-Machine Communication

Machine-to-machine communication is just what it sounds like, according to this internet of things dedicated site: It’s “A broad label that can be used to describe any technology that enables networked devices to exchange information and perform actions without the manual assistance of humans.”

M2M is similar to the term “The Internet of Things,” but there are differences, as this article sums up nicely. Namely, IoT always relays info through the cloud and has unlimited integration options, while M2M often communicates through wires or cellular networks and may not require the internet at all. That also means that M2M communication integrations can be more limited because they may all communicate in different ways.

Regardless of which type of connection machines use in the future, they’re able to do it increasingly easily.

Cognitive Computing

Again, definitions may vary for the term “cognitive computing,” but it’s generally understood to refer to platforms that employ artificial intelligence and signal processing. This type of technology results in the ability of computers to use relevant data and to act on their own.

This Forbes columnist explains that “cognitive computing comes from a mashup of cognitive science — the study of the human brain and how it functions — and computer science.” Its goal is to “simulate human thought process in a computerized model.”

Manufacturers that don’t leverage this tech will be threatened by newer, more agile startups that do. #receptionistapp Click To TweetFor example, cognitive computing might allow machines to adjust settings, shut off power, or sound an alarm, if a certain combination of criteria are met.

The technologies that are converging to potentially create a fourth industrial revolution (cyber-physical systems, big data analytics, human-machine interfaces, machine-to-machine communication and cognitive computing) all continue to advance. Although it’s sometimes difficult for factories to make quick changes to adapt to these new tools, manufacturers that don’t take advantage of this technology may find themselves threatened by newer, more agile startups.

Interested in other ways to use data and monitoring tools to optimize your office? Check out 4 Modern Tools for the High-Tech Office, where we discuss a few other ways that offices can track space use, including conference room scheduling and visitor management software like The Receptionist.

Share this Post